The MOL Concept

When selecting the raw materials we use, we focus on maximum ecological safety. The sustainable use of raw materials saves resources and CO2 over the entire product life cycle – and thus also for you as a user and operator – as well as for us in the company. Against this background, all our long-life MOL catalysts are 100% recyclable via melting processes.

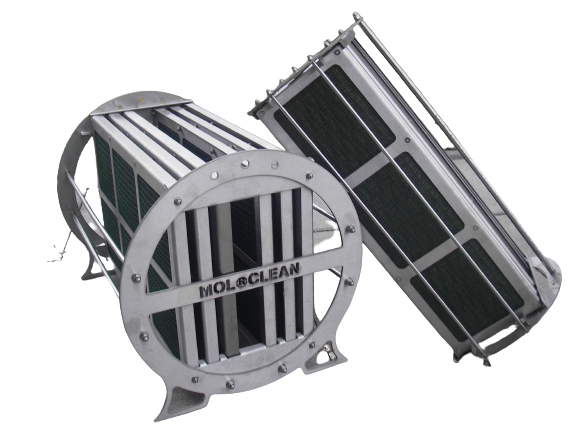

MOL®LIK

Biocide-free Catalyst Technology

The core of the technically established MOL®LIK technology is a high-performance ultra-thin metal catalyst foil made of nickel, chromium and iron with a proven mineral layer. In analogy to nature and using the latest findings from semiconductor technology, an electron exchange takes place with special metal foils. Fouling and deposits are removed and surfaces are cleaned in a sustainable and at the same time material-friendly way. In this way, bacteria – especially legionella – are deprived of protective and living space. The catalytic efficiency can be further increased by daylight. This is guaranteed by suitable integrated daylight LEDs.

When using the biocide-free MOL®LIK technology, legal regulations and standards such as the German VDI 6023 and the German Drinking Water Ordinance (TrinkwV) are safely complied with.

Your advantage when using the low-maintenance MOL®LIK technology:

- Clean systems

- Improved heat transfer and low pressure losses

- Long service life of the installed components

In addition to many years of use in industry, the MOL®LIK technology is suitable for permanent use in the drinking water sector. Typical cleaning routines are significantly reduced by the MOL technology. For you as a user, the durable MOL®LIK modules guarantee a high level of process reliability over many years.

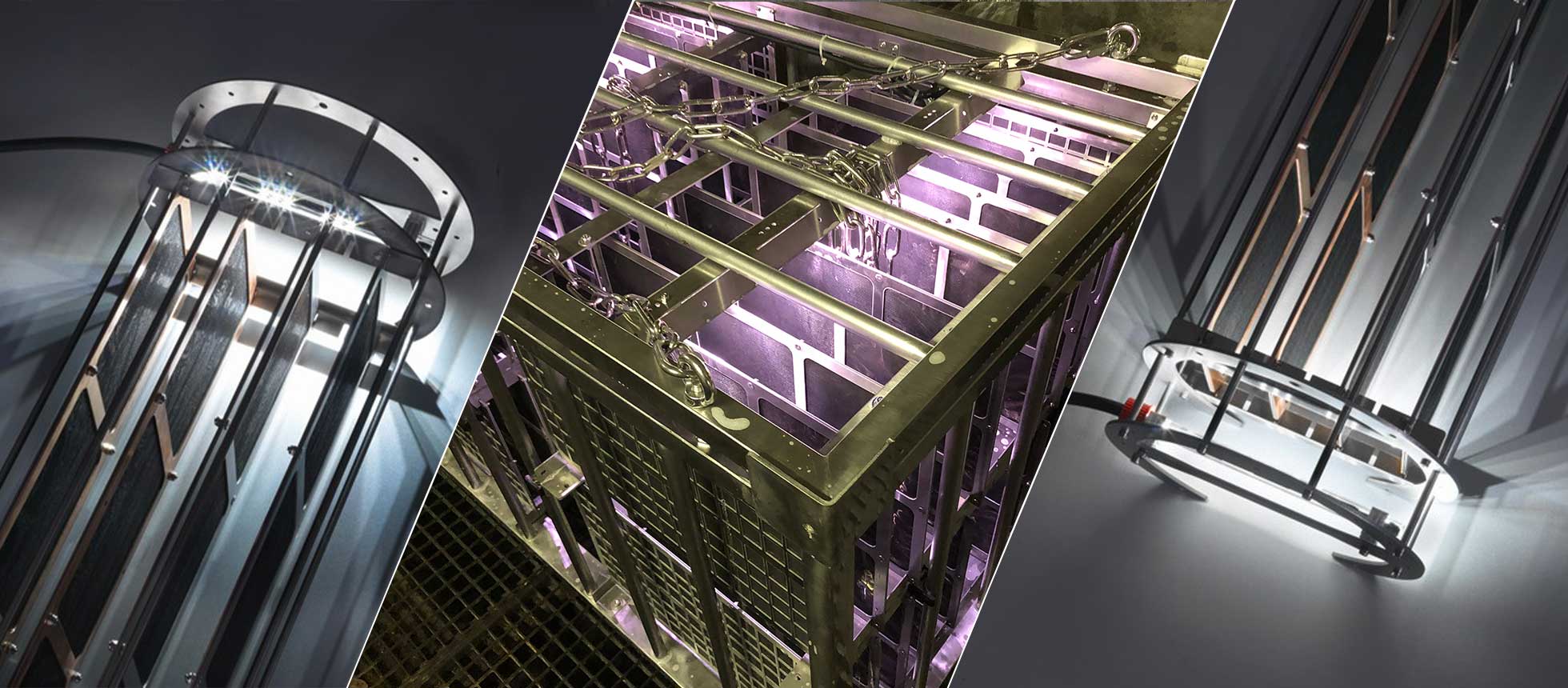

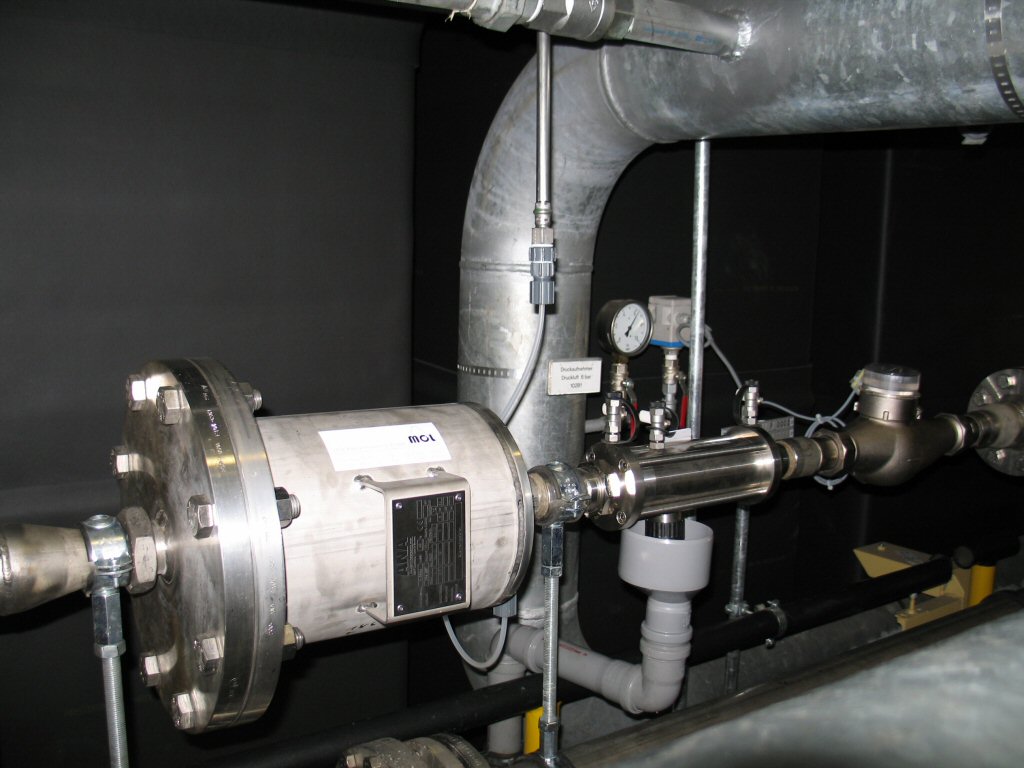

MOL®CLEAN

High Operational Safety and Quick Cleaning

Since 1998 on the market, the MOL®CLEAN process has proven itself reliably for intensive cleaning as well as for the permanent elimination of biofilms and deposits. Numerous applications prove that even complex performance systems of industrial plants can be operated permanently in compliance with regulations and with low maintenance.

With MOL®CLEAN you achieve:

- Clean systems

- Hygienic safety

- Technological operational safety

By using special wire mesh catalysts, the selective oxidation of germs to biosurfactants takes place in the presence of small amounts of MOL®aktiv E30 (special hydrogen peroxide-containing solution). The biosurfactants formed in this way are able to dissolve existing biofilms. This takes place without affecting the surface tension of the water. At the same time, the formation of toxic endotoxins is avoided.

With this technology, the biosurfactants dissolve any biofilm that may already be present in the system and prevent new growth. This deprives bacteria – especially Legionella – of protective and living space. By removing the biofilms, microbiologically induced corrosion, as well as limescale and rust, are prevented. In addition, suitable corrosion inhibitors can act efficiently on the then clean material surfaces.